Production departments

Mechanical precision turning

In the turning department of our precision mechanical workshop, next to some traditional machines, there are state-of-the-art machines such as CNC lathes with bar feeder. Thanks to our machinery, highly qualified staff and decades of experience, we are able to ensure high precision and product quality.

We offer, on small and medium sized products, different types of turning such as threads, flattening, parting, grooving and more. All our processes can be carried out on different types of materials.

We are also specialised in the production of single components, small or medium batches, even where complex mechanical processing is required.

Mazak Integrex J-200S

- Smooth Technology control

- Spindle and counter spindle F

- Milling and turning head

- Tool magazine up to 36

- RPM 11.000 min.

- Power 11 kW

Hanwa XD38II

- 10 Axes (6 linear + 4 rotary)

- Siemens 828D numerical control

- 2 Processes

- 2 Electrospindles

- Up to 25 tools

- Max 11 driven tools

Tsugami CNC turning centre B0206E-III

- GE Fanuc control

- 6000 rpm

- Automatic bar feeder ALPHA 320S3

- Oil mist purifier for Tsugami BO206E-III

- Processing kit

- Three-phase 15kVa autotransformer

- Container for Tsugami BO

CNC lathe NAKAMURA TOME AS-200L

- Fanuc Control Series 0T D6G1-07.0

- 6000 rpm

- Hydrobar feeder LNS

- Scahublin and Bellegrandi racks

- Autocentring Autoblock

CNC lathe NAKAMURA TOME TMC20

- GE Fanuc control

- 6000 rpm

- Hydrobar feeder LNS

SCHAUBLIN 125 CCN lathe

- GE Fanuc control

- 5000 rpm

- Hydrobar feeder LNS

HARRISON Alpha 1400S Plus lathe

- GE Fanuc control

- 2500 rpm

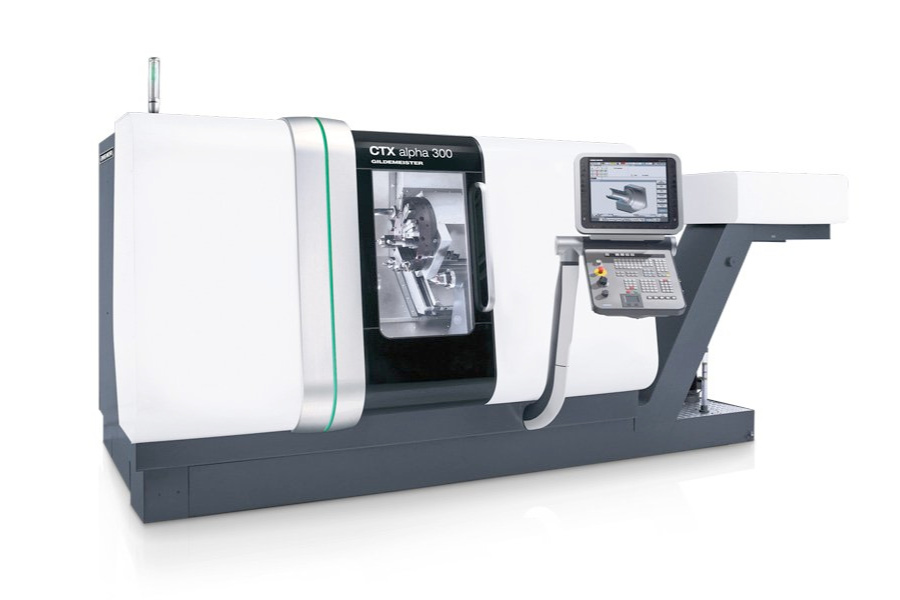

DMG GILDEMEISTER CTX alpha 300 lathe

- Simes 840D control

- Motorised tools

- Loader for LNS blanks

Special processing and customization

In addition to the machining operations made possible by the turning, milling and grinding departments, our company offers its customers the possibility of customising precision mechanical components as well as special machining operations, also thanks to a network of certified partners.